Metal roof decks, common in Vancouver’s commercial and modern residential buildings, offer durability and aesthetic appeal but pose unique insulation challenges due to their high thermal conductivity. In Climate Zone 5’s wet, temperate environment, improper insulation can lead to condensation, mold, and energy loss, compromising building performance. At Simon Green Works, we apply building science to create robust, energy-efficient roof assemblies. This article explores the optimal insulation strategy for metal roof decks, covering material choices, installation techniques, air sealing, and Vancouver-specific considerations to ensure long-lasting, high-performance roofs.

Why Exterior Insulation is Essential

Metal’s thermal conductivity, 400 times higher than wood, makes it prone to condensation when warm, moist interior air meets a cold deck, especially in Vancouver’s humid winters (85–95% RH). Installing all insulation above the deck keeps the deck at interior-like temperatures (20–22°C), eliminating condensation risks for most building uses. This approach, unlike cavity or hybrid insulation, avoids moisture traps and enhances energy efficiency by minimizing thermal bridging. Blown-in or batt insulation in interstitial cavities is unsuitable, as air leakage through imperfect vapor barriers can deposit moisture, leading to rot. In Vancouver, where flat roofs dominate urban designs, exterior rigid insulation is the only reliable strategy for metal decks.

Preferred Insulation Materials

Rigid insulation, applied in multiple layers with staggered joints, is ideal for metal roof decks. High-density polyisocyanurate (polyiso, R-7/inch) is favored for its high R-value, compressive strength (20–40 psi), and moisture resistance with coated glass facers, achieving R-20–30 with 75–100 mm (3–4 inches). Extruded polystyrene (XPS, R-5/inch) and expanded polystyrene (EPS, R-4/inch) are cost-effective alternatives, though XPS’s blowing agents raise sustainability concerns. Rigid mineral wool (R-4.3/inch) offers fire resistance and acoustic benefits, ideal for Vancouver’s urban settings, but requires thicker layers (100–125 mm for R-20). Wood fiber insulation, while eco-friendly, is less common due to moisture sensitivity.

A self-adhered or fluid-applied air and vapor barrier, installed over gypsum sheathing above the metal deck, ensures airtightness, critical to prevent moisture migration. In Vancouver’s wet climate, polyiso or mineral wool are preferred for their balance of performance and durability, meeting BC’s Step Code requirements (R-20 minimum).

Installation Techniques for Performance

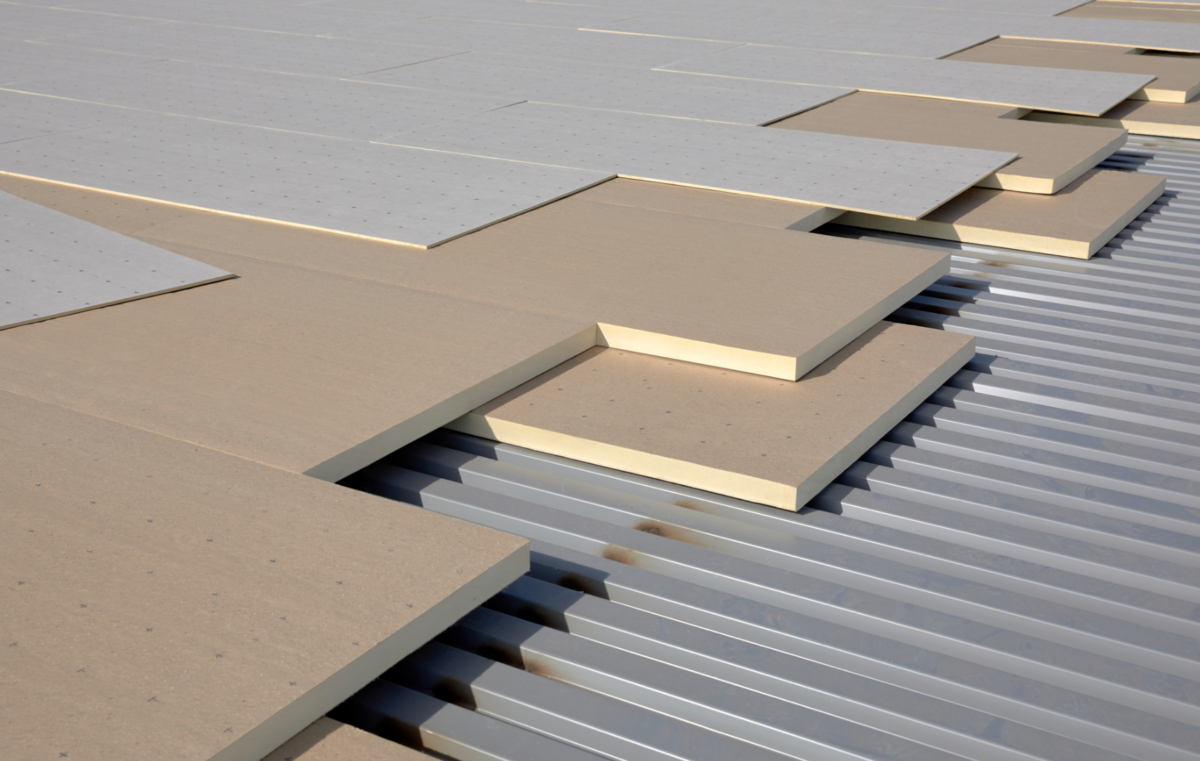

The insulation assembly begins with a fluted metal deck, followed by gypsum sheathing as a flat substrate for a self-adhered air and vapor barrier. Multiple layers of rigid insulation, with staggered and offset joints, prevent convective looping and membrane deformities. The first insulation layer is mechanically fastened to the deck, while subsequent layers are adhered to minimize thermal bridging through fasteners, a key concern with metal’s conductivity. A compatible cover board (e.g., gypsum) supports the roof membrane (TPO or PVC), which is adhered or heat-welded for watertightness.

For acoustical perforated decks, common in Vancouver’s commercial spaces, closed-cell spray foam fills corrugations to seal penetrations without compromising acoustics, followed by a gypsum cover board and vapor barrier. At parapets, insulation wraps around framing or extends below to maintain thermal continuity, preventing condensation. In Vancouver’s rainy seasons, temporary coverings protect insulation during installation to avoid moisture entrapment.

Air Sealing for Moisture Control

Air leakage, transporting moisture at rates far higher than diffusion, is a primary concern for metal decks. A self-adhered vapor barrier, taped at seams and integrated with exterior wall WRBs, creates a continuous air control layer. For perforated decks, spray foam sealing, combined with a cover board, ensures airtightness. At parapets, the barrier extends up and over, taped to wall membranes, preventing air infiltration. In Vancouver’s humid climate, meticulous air sealing is critical to avoid condensation on cold deck surfaces, especially in unvented assemblies with exterior insulation.

Vancouver-Specific Considerations

Vancouver’s Climate Zone 5, with heavy rainfall and mild winters, demands insulation that prioritizes moisture control and seismic resilience. Exterior rigid insulation, achieving R-20–30, meets local codes and Passive House standards, while mineral wool’s fire resistance suits urban fire risks. A minimum 2% deck slope ensures drainage to scuppers, critical for flat roofs in high-precipitation areas. Seismic codes require robust deck anchorage (50 kN/m), and insulation must withstand dynamic loads, per BC’s 0.46g acceleration standards. Urban density limits access, favoring modular insulation systems.

Green roofs or usable roof decks, common in Vancouver’s sustainable buildings, increase insulation loads (200–500 kg/m² wet), requiring high-compressive-strength materials like polyiso. Regular maintenance—clearing drains and inspecting seams—is essential in rainy seasons to protect insulation integrity. Homeowners should consult structural engineers to confirm load capacity and explore municipal incentives for energy-efficient roofing, aligning with Vancouver’s 2030 carbon-neutral goals.

Why Simon Green Works?

Simon Green Works delivers metal roof insulation solutions rooted in building science, tailored to Vancouver’s challenging climate. Our expertise ensures energy-efficient, durable roofs that enhance comfort and sustainability. Ready to optimize your metal roof? Contact us for a tailored consultation.

Sources

This article draws on insights from Sharif Asiri’s article, “Insulating Metal Roof Decks,” published by ASIRI Designs (Insulating Metal Roof Decks). Additional perspectives are informed by “Steel Deck Insulation” from ROCKWOOL (Steel Deck Insulation) and “OneDek® Insulated Roof Deck System” from AWIP (OneDek® Insulated Roof Deck System).