Stucco parapet walls, prized for their aesthetic appeal in Vancouver’s modern and Spanish-style homes, are notoriously prone to moisture issues due to their reservoir-like nature. In Climate Zone 5’s wet, temperate environment, with heavy rainfall and high humidity, poor detailing can lead to leaks, rot, and structural damage, especially at exposed parapet transitions. At Simon Green Works, we leverage building science to create durable, moisture-free stucco parapets. This article explores stucco’s moisture challenges, drainage strategies, waterproofing techniques, vapor control, and Vancouver-specific considerations, ensuring robust flat roof assemblies.

The Challenge of Stucco as a Reservoir Cladding

Stucco, a cement-based plaster, absorbs and stores water like a sponge, redistributing it to adjacent materials through capillary action. In Vancouver’s high-rainfall climate, this reservoir behavior drives water into parapet assemblies, especially at roof-to-wall junctions lacking overhangs. Solar-driven vapor, intensified by temperature gradients (0–25°C), pushes moisture inward, condensing on impermeable membranes if unchecked. Traditional repairs, like sealing cracks with caulk, fail to address this core issue, as new cracks form from water absorption and building movement, leading to rot within years. Effective stucco parapets assume water infiltration and prioritize drainage and drying.

Drainage Strategies for Moisture Control

To prevent moisture buildup, stucco must be uncoupled from the wall assembly with a drainage gap. A high-density polyethylene dimple mat (e.g., Delta MS, 8–10 mm thick) or entangled mesh with filter fabric creates a capillary break and drainage plane, alleviating hydrostatic pressure. The mat, installed between the weather resistive barrier (WRB) and stucco, allows water to drain downward and air to circulate, promoting drying. Building codes require two layers of building paper behind stucco to serve as a bond break, but dimple mats offer superior performance by ensuring continuous drainage, critical in Vancouver’s saturated conditions.

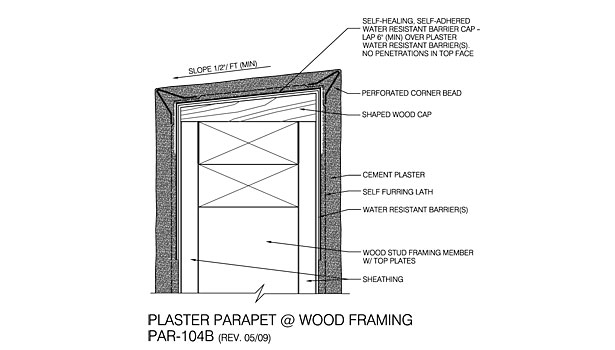

Waterproofing and Flashing Techniques

Waterproofing stucco parapets demands a continuous water control layer. A self-adhered or fluid-applied WRB (e.g., Prosoco CAT-5 or Hydrogap SA, 10 perms) bonds to sheathing, preventing air and water leakage. The roof membrane, preferably TPO or PVC, laps over the WRB at the parapet base, sealed with compatible flashing tape to avoid fish-mouthing. A flashing membrane, like SBS rubberized asphalt, connects the roof to the exterior WRB, ensuring monolithic protection. In Vancouver, where parapets face extreme weathering, airtight WRBs outperform housewraps, which can leak at seams under wind-driven rain.

Controlling Vapor Drive

Stucco’s moisture storage drives vapor inward when heated by the sun, risking condensation on cold, impermeable membranes. A dimple mat serves as a Class II vapor retarder (0.1–1.0 perms), throttling inward vapor while allowing outward drying via its air gap, unlike polyethylene sheets that trap moisture. Alternatively, rigid foam insulation (e.g., XPS, R-5/inch, 2 inches thick) outboard of the WRB acts as a vapor retarder, but requires a drainage gap (e.g., grooved XPS or Hydrogap SA) to permit drying. A less permeable WRB (10 perms) slows vapor flow, giving airflow time to remove moisture, critical in Vancouver’s humid summers.

Coping Details for Durability

Coping protects parapet tops from water ingress, and metal copings with drip edges are the most reliable, kicking water away from stucco facades. Coping stones or terracotta tiles, while aesthetic, absorb water and require a drainage gap and metal flashing (e.g., stainless steel with drip edge) to prevent leaks. Stucco-wrapped copings, wrapping around the parapet, pose the highest risk, requiring a continuous drainage gap from vertical to horizontal surfaces, backvented for airflow, and sloped framing to drain water inward. In Vancouver, metal copings are preferred for their longevity and compliance with local detailing standards.

Vancouver-Specific Considerations

Vancouver’s Climate Zone 5, with 1200 mm rainfall and mild, humid winters, amplifies stucco parapet vulnerabilities. Dimple mats and airtight WRBs protect against saturation, while seismic codes (0.46g acceleration) require robust framing anchorage (50 kN/m). Green roofs or roof decks, common in Vancouver’s sustainable buildings, increase loads (200–500 kg/m²), demanding durable copings. Local bylaws mandate robust flashing at parapets, and green building incentives, like density bonuses ($100,000–500,000), support high-performance assemblies. Quarterly maintenance—inspecting copings and clearing drainage paths—is essential in rainy seasons. Homeowners should consult structural engineers to ensure load capacity and code compliance, leveraging local expertise for resilient designs.

Why Simon Green Works?

Simon Green Works crafts moisture-free stucco parapet solutions, rooted in building science and tailored to Vancouver’s wet climate. Our expertise ensures durable, high-performance assemblies that enhance your home’s longevity. Ready to transform your flat roof? Contact us for a tailored consultation.

Sources

This article draws on insights from Sharif Asiri’s article, “How to Achieve Moisture-Free Stucco Parapets,” published by ASIRI Designs (How to Achieve Moisture-Free Stucco Parapets). Additional perspectives are informed by “Best Practice for Stucco Parapet Caps” from JLC Online (Best Practice for Stucco Parapet Caps) and “Guide to Creating Weatherproof Parapet Walls” from Premier Guarantee (Guide to Creating Weatherproof Parapet Walls).