Moisture management is critical for Vancouver homes in Climate Zone 5, where heavy rainfall (1200 mm annually) and high humidity (85–95% RH) threaten building envelopes with mold, rot, and structural damage. Traditional vapor barriers, like polyethylene sheets, often trap moisture, exacerbating issues in the region’s mixed climate of cold winters and humid summers. Smart vapor barriers, with variable permeability, adapt to seasonal humidity changes, restricting vapor in winter while allowing drying in summer. At Simon Green Works, we leverage building science to integrate smart vapor barriers into high-performance homes, enhancing durability and energy efficiency. This guide explores how smart vapor barriers work, their installation, benefits, and Vancouver-specific considerations for resilient, sustainable homes.

How Smart Vapor Barriers Work

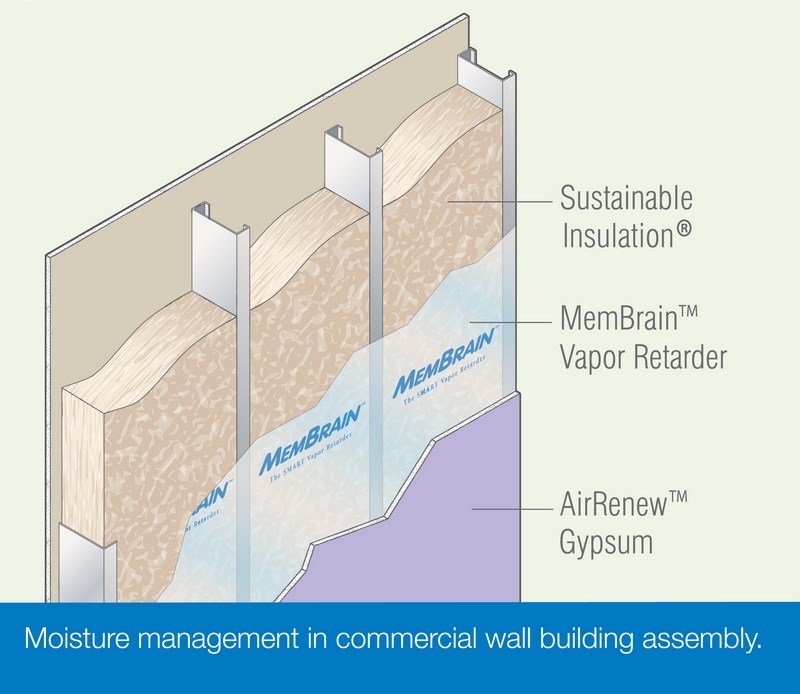

Smart vapor barriers, typically made from polyamide or proprietary polymer films, adjust their vapor permeance based on ambient humidity. In winter, with low humidity (<60% RH), they act as vapor retarders (0.1–1.0 perms), blocking warm, moist indoor air from reaching cold exterior sheathing, preventing condensation. In summer, with higher humidity (>60% RH), their permeance increases (5–20 perms), allowing trapped moisture to dry inward, reducing mold risks. This dynamic behavior outperforms static polyethylene barriers (0.05 perms), which trap moisture and limit drying in Vancouver’s variable climate. Smart barriers maintain airtightness, complementing weather resistive barriers (WRBs) to control air-driven moisture, which deposits 30 times more water than diffusion.

Installation Best Practices

Proper installation ensures smart vapor barriers perform optimally. Applied on the warm side of the wall assembly (interior in Vancouver’s winter-dominated climate), they are taped at seams, edges, and penetrations with compatible air-sealing tape to create a continuous barrier. For new construction, the barrier is installed over studs before drywall, integrated with a service cavity (e.g., 25 mm strapping) to protect against electrical or plumbing penetrations. In retrofits, blown-in insulation like cellulose (R-3.7/inch) pairs with smart barriers, applied via small access holes, minimizing disruption. The barrier must tie into WRBs at window and door openings, using fluid-applied flashings to prevent air leaks. In Vancouver’s wet climate, meticulous taping and sealing are critical to avoid moisture infiltration at seams.

Benefits for Energy Efficiency and Durability

Smart vapor barriers enhance energy efficiency by maintaining insulation performance, preventing moisture from degrading R-values (e.g., cellulose drops 20% when wet). By controlling air leakage, they reduce heat loss, saving 10–20% on heating costs ($200–$500 annually for a 200 m² home). Their drying capacity minimizes mold and rot, extending wall assembly lifespan by decades, a key advantage in Vancouver’s humid environment. Unlike polyethylene, which requires perfect installation to avoid trapping moisture, smart barriers are forgiving, adapting to construction imperfections and seasonal shifts. They also support indoor air quality by preventing moisture-related mold growth, aligning with Vancouver’s health-focused building standards.

Choosing the Right Smart Vapor Barrier

Selecting a smart vapor barrier depends on wall assembly and climate needs. Polyamide-based membranes, like Intello Plus or DB+, offer high permeance swings (0.8–13 perms) and reinforcement for durability, ideal for Vancouver’s mixed climate. Proprietary films, like Majrex, provide directional drying (inward-focused), suited for retrofits with exterior WRBs. For high-humidity spaces (e.g., bathrooms), barriers with lower maximum permeance (e.g., 5 perms) prevent excessive vapor flow. Compatibility with insulation (e.g., mineral wool, cellulose) and WRBs (10–20 perms) ensures balanced drying. In Vancouver, where summer vapor drive can push exterior moisture inward, barriers with inward drying capacity are critical to complement vapor-permeable insulation.

Vancouver-Specific Considerations

Vancouver’s Climate Zone 5 demands vapor barriers that address both winter condensation and summer humidity. Smart barriers, with variable permeance, prevent winter moisture buildup on sheathing (dew point ~10°C) while allowing summer drying, unlike polyethylene, which risks trapping moisture in air-conditioned homes. Seismic codes (0.46g acceleration) require secure barrier installation, integrated with structural bracing (50 kN/m). Urban density limits exterior access, favoring interior-applied barriers for retrofits. Green building incentives, like CleanBC rebates ($2,000–$12,500) and density bonuses ($100,000–$500,000), support smart barrier use in net-zero projects. Homeowners must ensure compatibility with existing WRBs and test for moisture issues before retrofitting, consulting engineers to meet BC Step Code (R-20 minimum) and local bylaws.

Why Simon Green Works?

Simon Green Works delivers smart vapor barrier solutions tailored to Vancouver’s wet, temperate climate, ensuring energy-efficient, durable homes. Our building science expertise navigates permitting and design challenges to protect your investment. Ready to enhance your home’s envelope? Contact us for a tailored consultation.

Sources

This article draws on insights from “Smart Vapor Retarders for Wall Assemblies” by CertainTeed (CertainTeed), “Smart Vapor Retarders” by Fine Homebuilding (Fine Homebuilding), and “The Difference Between Air Barriers and Vapor Barriers” by SOPREMA (SOPREMA).